Installation of sewage pumping stations

Comprehensive approach: from design to commissioning. Professional installation of sewage pumping stations with quality assurance and maintenance

Selection of a sewage pumping station

- The pumping equipment must be duplicated

- For sewage, it is necessary to use pumps with cutting edges

- The capacity of the bottom part of the sewage pumping station should ensure the long-term operation of the pumping equipment. This positively affects the operational period and provides an emergency reserve in case the incoming sewage exceeds the calculated amount

- The sewage pumping station must be equipped with ventilation

-

When selecting a pump, it is important to consider the length of the pipeline, elevation differences, potential freezing, and other specific characteristics of the site

Algorithm for creating a pumping station

Formation of a Technical Specification

Defines the main requirements for the system, the list of equipment for additional station outfitting, etc

Design of Pumping Stations

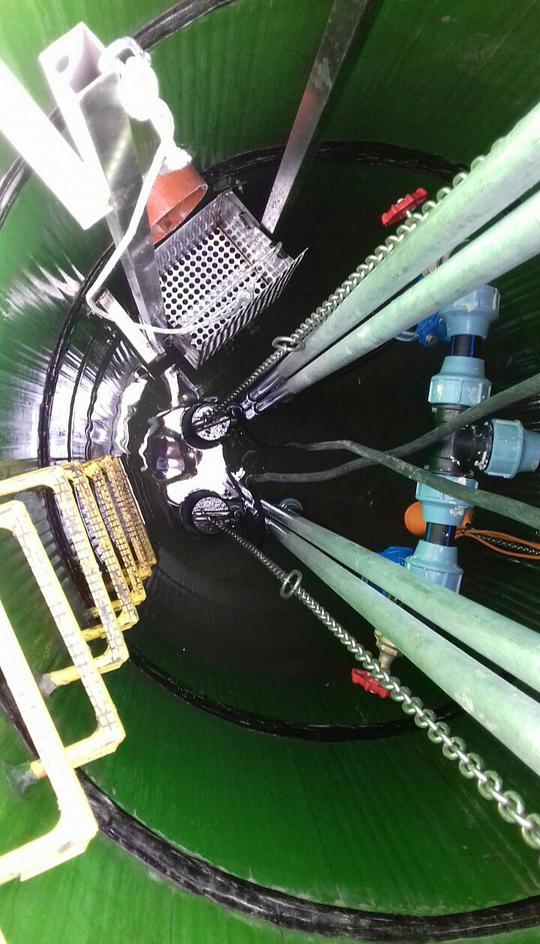

The housing is manufactured, pumps, components, and necessary control systems are installed

Installation

After installation, quality checks are performed on the station and it is launched into the external sewage network

Important

When designing pumping stations, the features of the landscape, operating modes, and the type and volume of the pumped effluents are taken into account

Additional equipment for the pumping station

- Automation: control panel, level control floats, emergency alarm, and, if necessary, an SMS notification system;

- System for securing and removing pumps;

- Discharge pipelines with check valves, shut-off valves, etc;

- The above-ground part of the station in the form of a cast iron manhole or a separate building.